|

Great Lakes Drain System™ is a unique foundation and surface drainage system that utilizes

current manufactured drainage strips to our specification in conjunction with our patent pending

fittings. This system provides superior water management, measurable

time saving, easy installation at a cost effective price!

The need for an effective drainage system has always played a vital role

in the construction industry and in the development of new and improved products.

As a result of these efforts you can now use Great Lakes Drain System™ in place of conventional crushed stone and

perforated pipe. Below are the critical components that make up the

assembly.

|

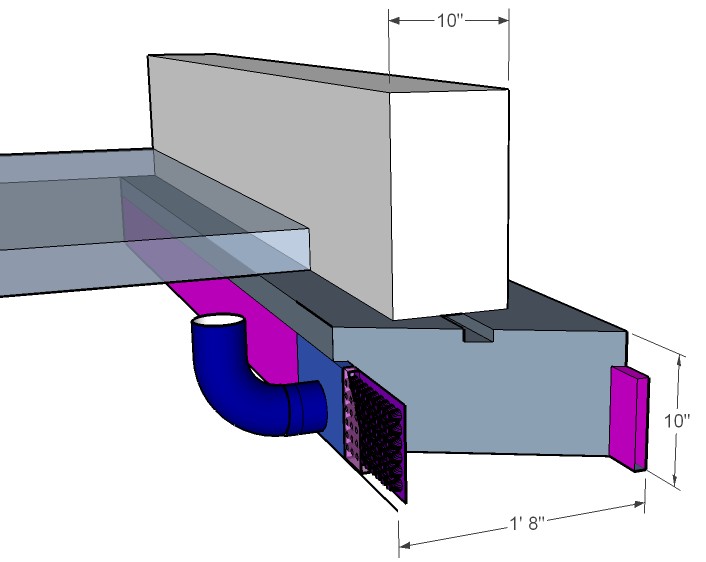

Drain System

Installation |

Great Lakes Drain System™

composite drainage system rendering shown below

(click here to actual product photos)

|

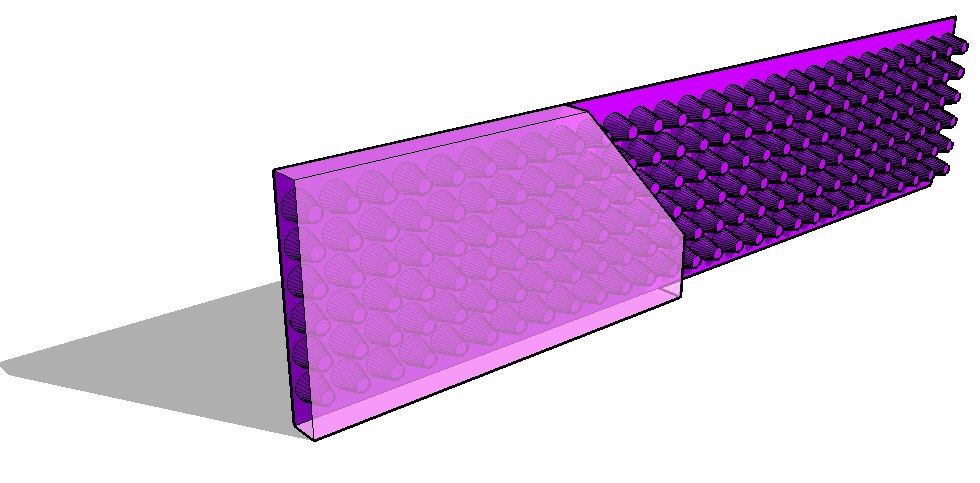

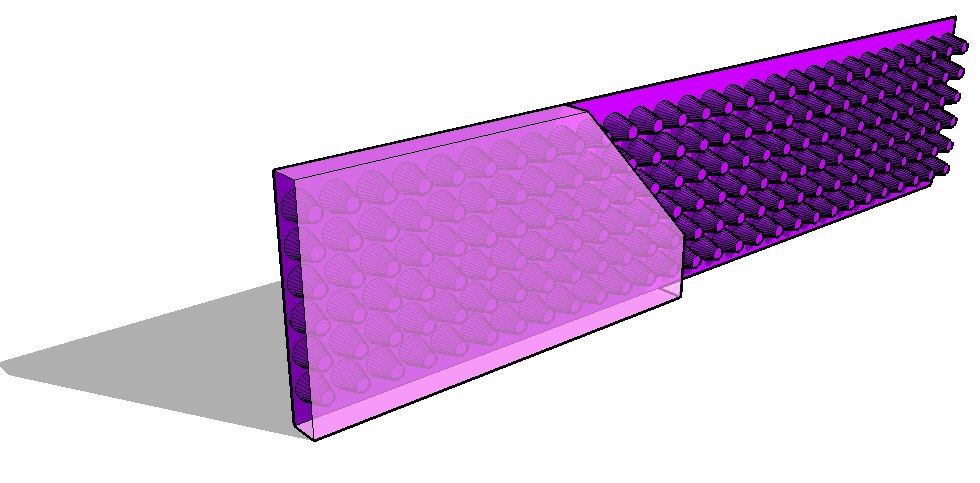

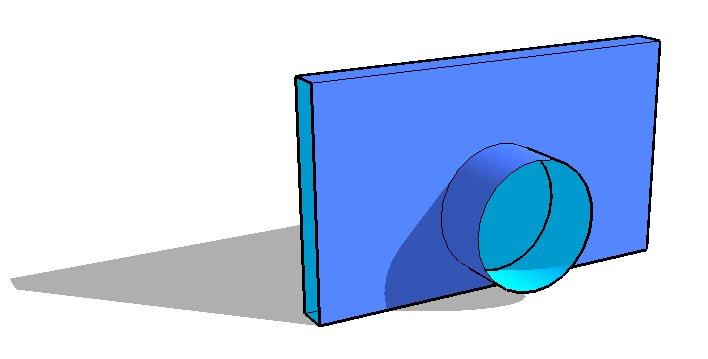

Strip Drain

Modular Drainage System is a modular composite drainage and collection

system consisting of

3-dimensional dimpled or honeycombed polymeric high flow drainage core

that is wrapped

with a

geosynthetic

non-woven filter fabric.

This allows water to pass through to the drain core without requiring

peastone for easy removal by

sump or storm drain system.

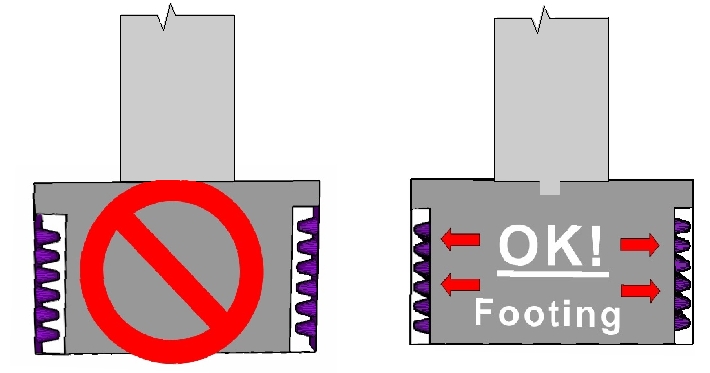

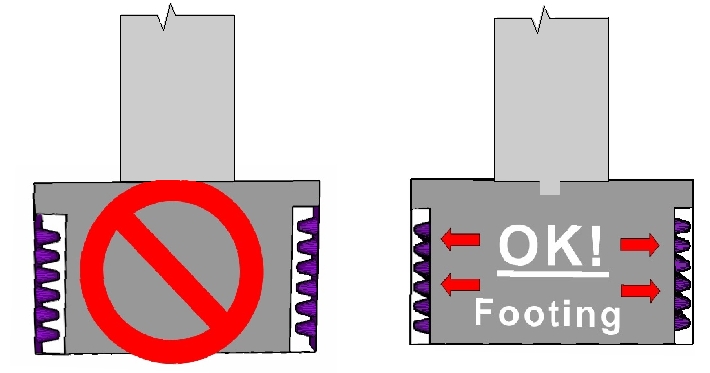

The graphic above shows both the

incorrect and the correct positioning of the strip drain in poured

footing. The dimpled

sections always face away from the vertical footing surface as shown.

|

Strip

Drain |

|

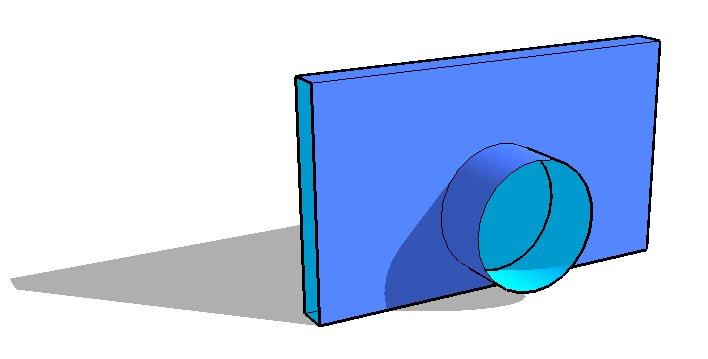

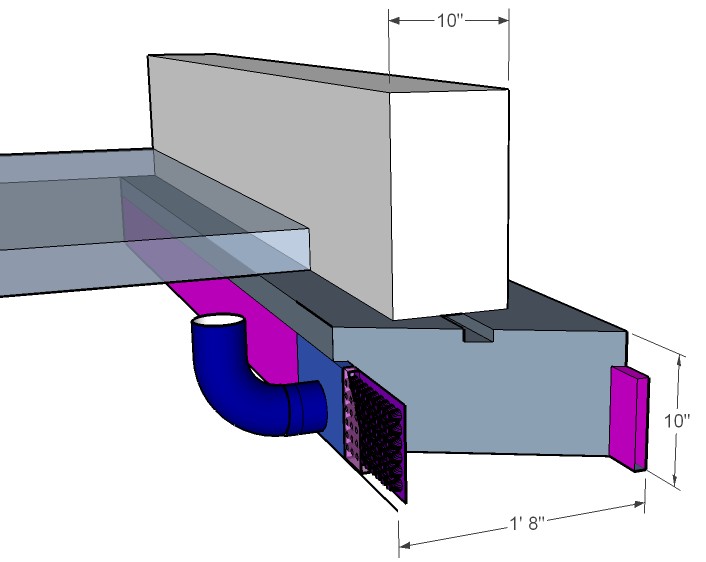

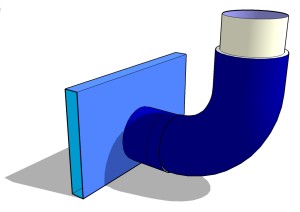

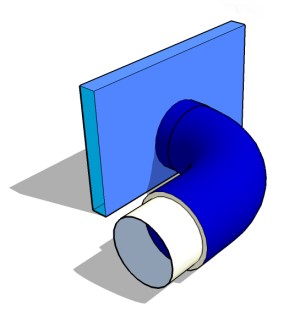

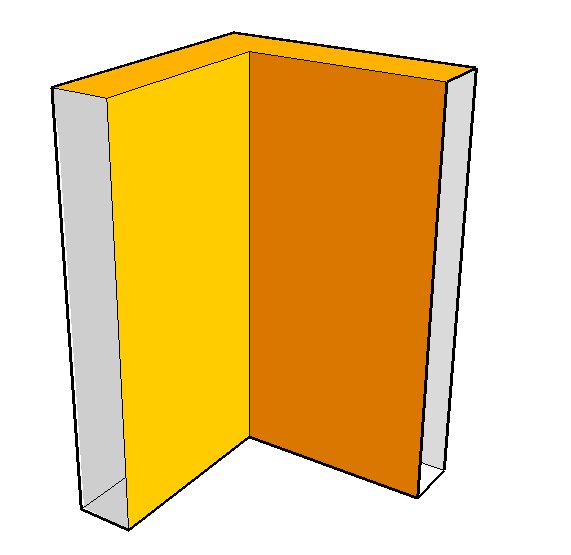

Side-Out

Side-out components

receive horizontal strip drain sections into each side [note positive stop prevents

any strip

drain overlapping, maximizing water flow]. The side-out also

connects a 4" drain tile section/bleeder (see red bleeder detail

below) through footing and to interior

drain system. |

Side-Out |

|

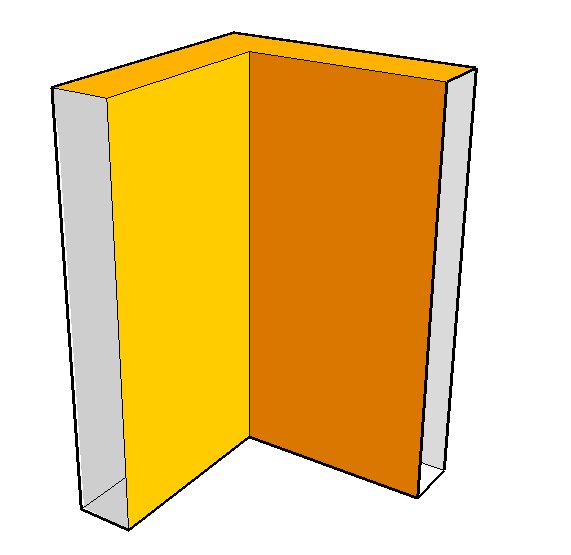

90 Degree Corner

The corners

fitting are used both as

inside and outside corners on horizontal drain strip. Vertical strips

require a corner at the outside base of footer. The minimum

recommendations for vertical strip drain is to place one at each beam

pocket and at centerline of each window to reduce hydrostatic

pressure at critical areas. [see other pages for details] |

90 Degree

Corner |

|

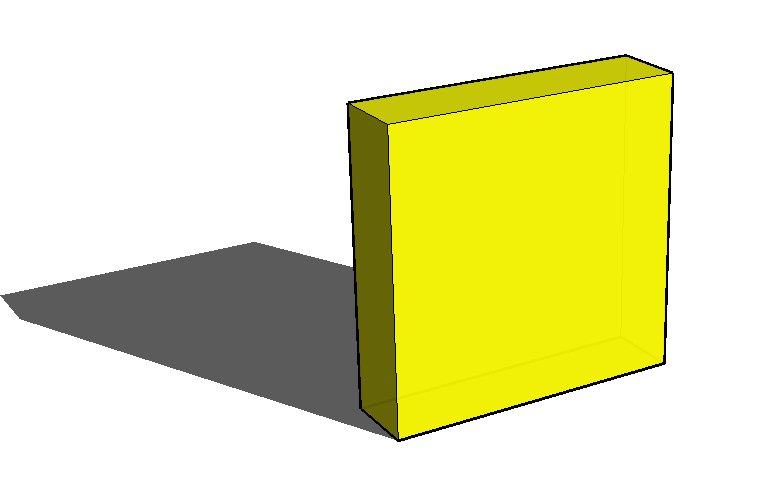

End Cap

End caps

are to be used at top of vertical strip drain. Note:

vertical strip drain should should reach the sill plate. The strip

drain should be field cut one to two inches below final grade,

concealing the strip drain and end cap.

|

End Cap |

|

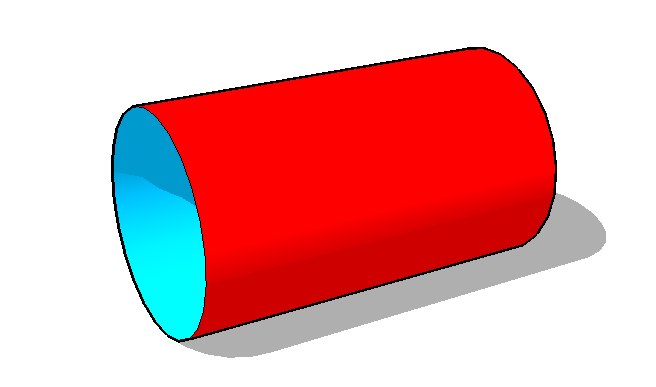

4" Drain Tile

Round 4" drain tile

is connected to

the side-out to move the exterior drain system water through the footing

and connect to the interior drainage system for removal by the sump or

storm drain. |

4"

Drain Tile |

Great Lakes Drain System™ Great Lakes Drain System™

Radon Vent and Egress Window & Walkout Drain Fittings.

Click in "New" of picture to go to

page |

|

|

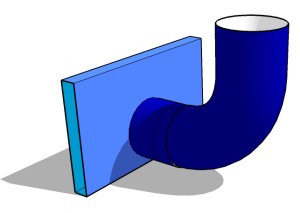

Vertical 90 Degree 4"

Solid Pipe Connector Assembly for RADON VENT for Basement

(accommodates 4" solid pipe for venting

radon)

|

|

|

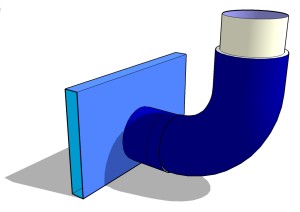

Vertical 90 Degree 4"

Drain Connector

Assembly for Egress or Basement Window.

(for flexible drain tile) |

|

|

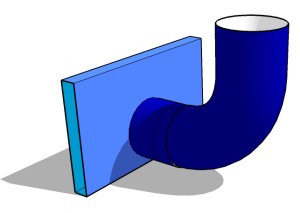

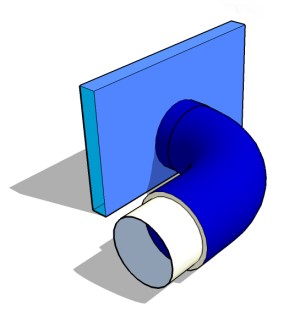

Horizontal 90 Degree 4"

Drain Connector

Assembly for Walkout & Sump Pumps

(for flexible drain tile) |

|

The installation overview page shows the

color coded product use.

Why are foundation drainage and

water management systems important?

There are

several factors in understanding why basement foundations can leak and how to

protect your foundation from moisture penetration. Whether you have a block

basement or a solid concrete poured wall, it is important to move the water away

from potential cracks that will occur over time in your foundation [note: cracks

are caused by soil differential or settling, thermal change, lateral pressure &

drying]. These

cracks don't have to be a problem!

There are four

important factors to consider to protect your basement and it's contents from

water;

-

Gutter and Down Spout.

-

Positive Grade that moves the water away from the

foundation,

-

Waterproofing

-

Foundation Drainage System.

When water

saturates the soils around your foundation, it creates hydrostatic pressure.

This pressure can weaken waterproofing membranes and will compromise

your warranty if you cannot show proper water management by using gutters and positive grade

to move water away the home.

A good drainage

system actually works to dewater the soils around your home and eliminates

hydrostatic pressure.

How do typical drainage systems work?

Footings are poured with small sections of 4" drain tile placed approximately

every 25' feet. Then walls are blocked or poured. Now a backup crew removes

forming equipment allowing for laborers to place yards of peastone around the

exterior of the foundation. Then they place 4" round drain tile around the entire

foundation, followed by more peastone over the newly placed drain tile. The

peastone is to help protect the drain tile from being crushed and help filter

the water.

The disadvantage of conventional 4" drain tile are 5 fold;

- There is always an additional trip to place the drain tile and peastone.

- The cost of the stone, labor and equipment to place it.

- Since the Great Lakes Drain System™ drainage system is poured with the footing, you do not have the

same issues with potential cave-ins, standing water, snow removal or

scheduling for exterior peastone [the drainage system is completed when the

footing forms are removed].

- Flow rate of water through the system.

- The storage area required for storing and inventorying material.

Note the picture below comparing a 150' of 4" round drain tile to the same

amount of strip drain.

150' Round Drain Tile vs. 150' Strip Drain.

|

![]()